Today, I share an example of the use of operational excellence tools and pricniples in tourism. How do you apply industrial tools to your customers? Define your value proposition, identify bottlenecks, use poka yoke and visual management.

Lean principles also apply in the service sector. Even if the tools and methodologies were designed for physical objects, you can use them. It’s easy, you just have to know the theory and adapt it to adjust to the human being who is the object of the process: skiing.

Define the value proposition

Like any business, a ski resort needs to know who its customer is and what he or she buys. The customer is the skier, he buys quality glide time. He wants to be able to get on the ski slopes as long as possible, good quality snow and few people on the trails.

The added value offered by the ski resort is directly related to the skier’s activities. The time spent waiting for the lifts is therefore non-value added for him.

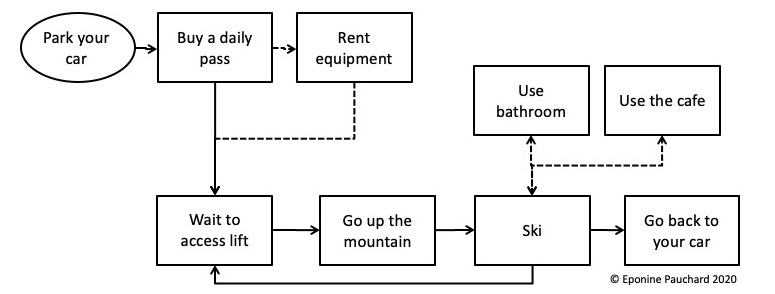

The “skiing” process incorporates all the skier’s activities. They can be classified: added value or non-added value, analysed and optimised with the operational excellence tools.

Identifying bottlenecks with the Theory of Constraints

The first action is to know where to put your efforts, if not obvious, a mapping of the value chain can help go into the details of the high-level process. This mapping will contain the different lifts with their flow, their average waiting time, the other services offered at the station.

The theory of constraints applies very well to make the right choices. Indeed, some skiers are faster and pass the others while they descent. But at the bottom of the resort, for queues at the lifts or in the cafeteria, they are in the same queue as the others.

With the theory of constraints it will be possible to identify the areas that need to be improved: the equipment rental, the number of slopes open at the top of each lift, number of lifts, etc.

The choice to invest in a more efficient lift will have to be made taking into account the available tracks. There is no point in bringing more skiers up, if the slopes are already crowded. This is what the theory of constraint is for: identifying current and future constraints.

Poka Yoke and Visual Management

To ensure a smooth flow of skiers, good signage is essential. If everyone asks where the toilets or a lift are, it’s as much time that employees don’t spend doing what brings value.

For employees, visual management, standardisation and poka-yoke is also a must. The Remarkables ski field, in New Zealand, offers a ski rental service. All the equipment is standard. There is one brand and one model of skis and shoes. On the other hand, all skis and shoes have a color code.

At the first counter, the skier takes his shoes. He has benches to put them on. At the second counter, he takes his skis, chosen according to his size and the size of his shoes. Black boot – black ski bindings, yellow boots – yellow bindings. Thus the ski already corresponds to the size of the shoe. The employee simply has to adjust the skier’s weight. The poles are self-service.

The team organizes itself with dedicated workstations:

- check the payment of the rental

- give boots,

- help put on/adjust the boots,

- adjust the skis,

- help choose the poles.

The setting tables incorporate computer screens. With an RFID chip system, coupled with the ski pass, the employee can check the status of the rental and have the weight of the skier. The workshop is 5S: all stations have the same tools and set-up, skis are sorted by size and identified.

In conclusion… why and how to optimize?

When your client is an integral part of your process, it takes more imagination and creativity to improve. With the emphasis on the customer experience, you have to integrate them into the design, listen to their remarks.