Want to identify waste? You are convinced that your organization can do better? Your ways have been the same for years and deserve an update? Do you know that some steps need to be reviewed in your processes? Are you wondering about the logic or reasons for some of your actions?

Congratulations, you have taken a step in the right direction: you have become aware of the need to improve your working methods! But where to start ?

I propose different methods to identify waste in your organization. When a problem is identified, the solution is easier to find! Whatever the subject, the most difficult exercise is to find the problem and then document and eradicate it.

Gemba walk

The principle of going to the field to see what is going on remains one of the most effective (but also the most time-consuming) ways to identify problems. In this case, it is not a matter of making a regular visit, but of sitting beside a person and watching them work for several hours. The observer can note anything that intrigues her: why do they go to a particular place to look for information? How come they copy the same thing twice? Direct observation provides many ideas. On the other hand, some waste could be due only to a person, who is less well trained, for example. This technique is therefore mainly aimed at first line managers, who know how to distinguish individual waste from “common” waste.

First line managers should regularly spend time watching their teams work to improve their effectiveness. Waste at the individual level can be easily corrected with information, training or redistribution of tasks. It is the primary role of managers to ensure that their teams are well trained and performing.

For “common” waste related to processes or tools, more research is needed to resolve waste. The theory of constraints can help decide what to start with.

Process mapping

At a more macro level, the team can map its process. That is, it will identify and write down all the steps required to complete an operation. This tool is particularly powerful when the process involves multiple people or sectors. By gathering them together to describe the steps, it is sometimes possible to remove some wastes quickly.

For example, an agent who receives the mail and staples the checks with the bills, while the billing area removes the staple before sending it to the collector. By discussing the process, it is possible to change the first step and put a paper clip, which simplifies life for everyone!

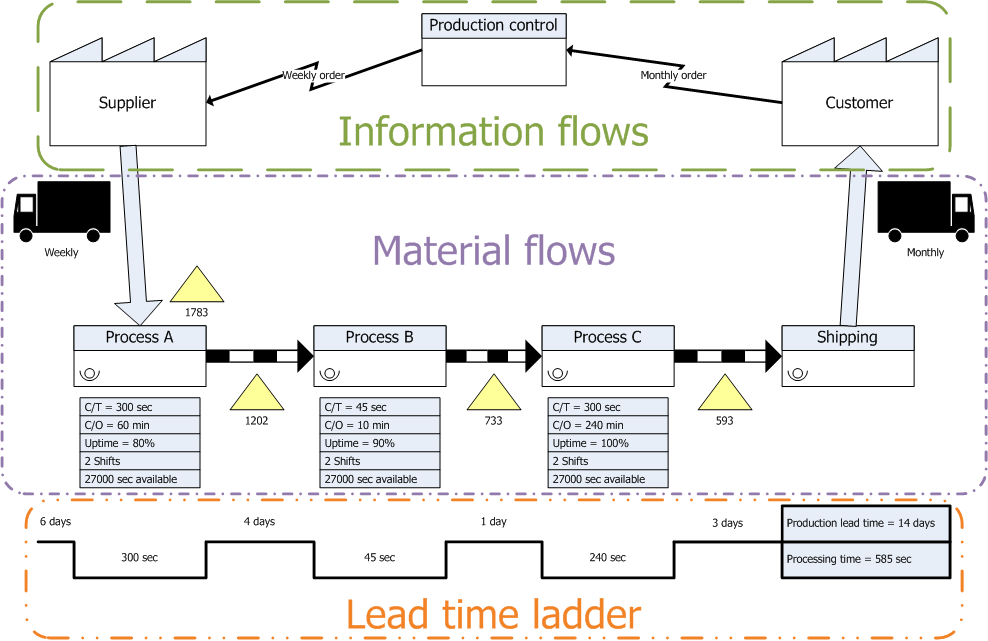

Value Stream mapping (VSM)

The second level of mapping includes the complete value chain and documents the key figures related to each step: how many people are working on this step? How long does it take? What is the inventory level before and after each step? How many units are processed or rejected at each step?

In the end, Value Stream Mapping (VSM) provides valuable information about the entire process and helps identify time-related wastes and errors.

Voice of the Employee (VoE) and Voice of the Customer (VoC).

Finally, two free and generous sources of information: your teams and your customers. Any complaint or suggestion should be listened to and analyzed. Remember, your customers are the ones who know best what they need and what they are willing to pay for. Even if you don’t like their vision, it’s good to hear from them and remember that they make you feel alive. Without going so far as to respond to the most incongruous requests, it is necessary to follow the trend of the comments and act accordingly. They live the processes, undergo the rules and give you another point of view.

Your teams know their work, they know what is working well, not so well or what is deteriorating. They should be the first to identify waste. You owe it to yourself to help them recognize the wastes. You also need to make sure that waste is removed, otherwise they won’t see the point in sharing it with you.

There are many ways to identify your waste, which is based on listening and observation, two qualities often forgotten in organizations. When will you spend time on the field?