I am always surprised to see how much the people with whom 5S actions are launched seem terrified by the magnitude of the task at hand. They do not see any interest in it. Yet 5S are part of our culture.

Have you ever argued with your spouse or children for putting the tape roll or vegetable peeler in the “wrong” place?

5S principles

Formalized in Japan for many years, the 5S is a method of workspace organization. It is based on visual information. This technique is based on the assumption that we work best when we have a well-organized work environment. What can be seen, from a distance… You will go through 5 steps: the 5 S. Each S stands for a word starting with an S in Japanese. The English translation isn’t perfect, but gives a good sense of each step.

5S is not natural and requires efforts to be implemented, but also to be maintained. This, in my opinion, is the only solution for a harmonious life in the community. I suggest you explore the 5S with three examples:

- At home : in the kitchen

- In an office.

- At a workstation.

Seiri (整理) / Sort

We all tend to pick up, collect and hold various items. “That might be useful someday.” “We might need it if …” The first step in 5S is to get rid of these items.

- The Kugelhof mold offered by your grandmother, which has never been used, does not deserve its place in a cabinet.

- Keeping three staplers in your drawer does not staple more or better.

- The jig for a part that has not been manufactured for 2 years no longer has a spot on the workbench.

This step can be difficult for some, for the sentimental ones, because source of many questions. “I have not used this item for a year, but maybe I might need it someday, or it could be for someone else.”

One of the solutions is to put these objects in a dedicated area, with specific rules. Anyone can take anything during 2 weeks then it is disposed. Alternatively, we keep these in a box. If no one has opened the box after 6 months, everything is thrown away.

Seiton (整頓) / Set in order

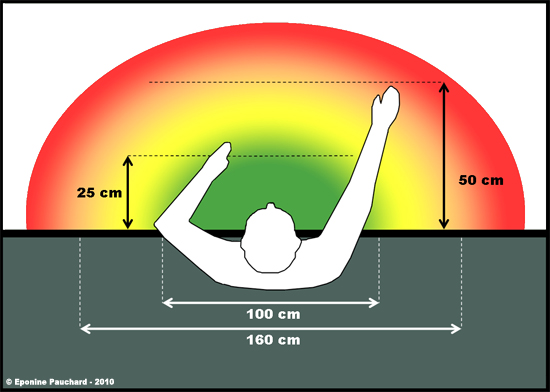

This second step requires reflection on the use of objects. The easiest way is to remove everything from the work area. You can then replace the objects according to their use: once an hour, a day, a week, or a month. Of course, what is most often used will be at hand. Objects used less than once a day can be stored in cupboards or drawers. That way, they will be protected from dust. What is used very rarely may be shared in common areas. They will be accessible by moving or stretching the arm.

- The kitchen knives are stored in a drawer or in height, on a magnetic rail for example (for safety). The other utensils can be placed in a pot next to the cooking zone. Finally, the fondue set can be stored all at the top or at the bottom of a shelf or cupboard.

- Depending on your tasks, your phone, a pencil pot (with only one pencil of each color) will be placed in the area at hand.

- The tools will be on the workbench. The cleaning and measuring equipment can be put in drawers. And the documentation will be displayed or placed further in a common area according to its use.

The main idea in this step is to minimize the impact on health and safety. The frequency of use and the weight of the objects will guide the choices. A place for everything and everything in its place

Seiso (清掃) / Shine

There are not really any tips for completing this step. It is obvious that a dust-free work environment on work areas and on moving areas is a guarantee of safety. The level of cleanliness required varies by industry or personal sensitivity. A welding shop does not have the same level of cleanliness as a pharmaceutical laboratory.

Seiketsu (清潔) / Standardize

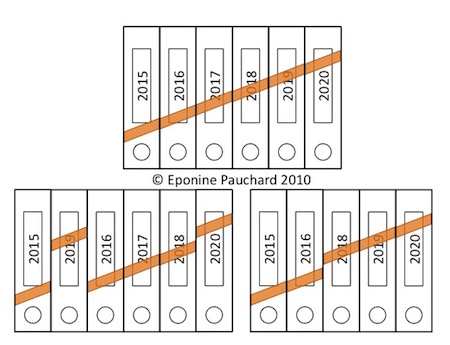

This stage is the one that concludes a 5S project, since it is necessary to standardize the organization decided upon. It is the time to mark the location chosen for each object. This marking facilitates the detection of missing tools and documents. It is also the time to write and share the operating procedures.

- With the whole family, you agree on the state of the kitchen at the end of each meal.

- Binders can be marked to know when they are missing (see figure below).

- At the end of each shift, or before each break, the workstation must be back to its standard.

Shitsuke (躾) / Sustain

The 5S ends with rigor, since the decided process must be maintained in the long term. In addition to keeping a clean and tidy environment, it must be updated with changes to the manufacturing process or product.

- In winter, gratin dishes are on the front. Later, in the summer, it is the barbecue accessories and lemonade bottles.

- The new documentation must replace the old one, which is then archived or destroyed.

- 5S audits to verify that the position is always up-to-date can be implemented.

Each team or employee must own their work area, make it effective.

The 5S is an ongoing process.